What's happening in my Model A Engine shop?

Blog

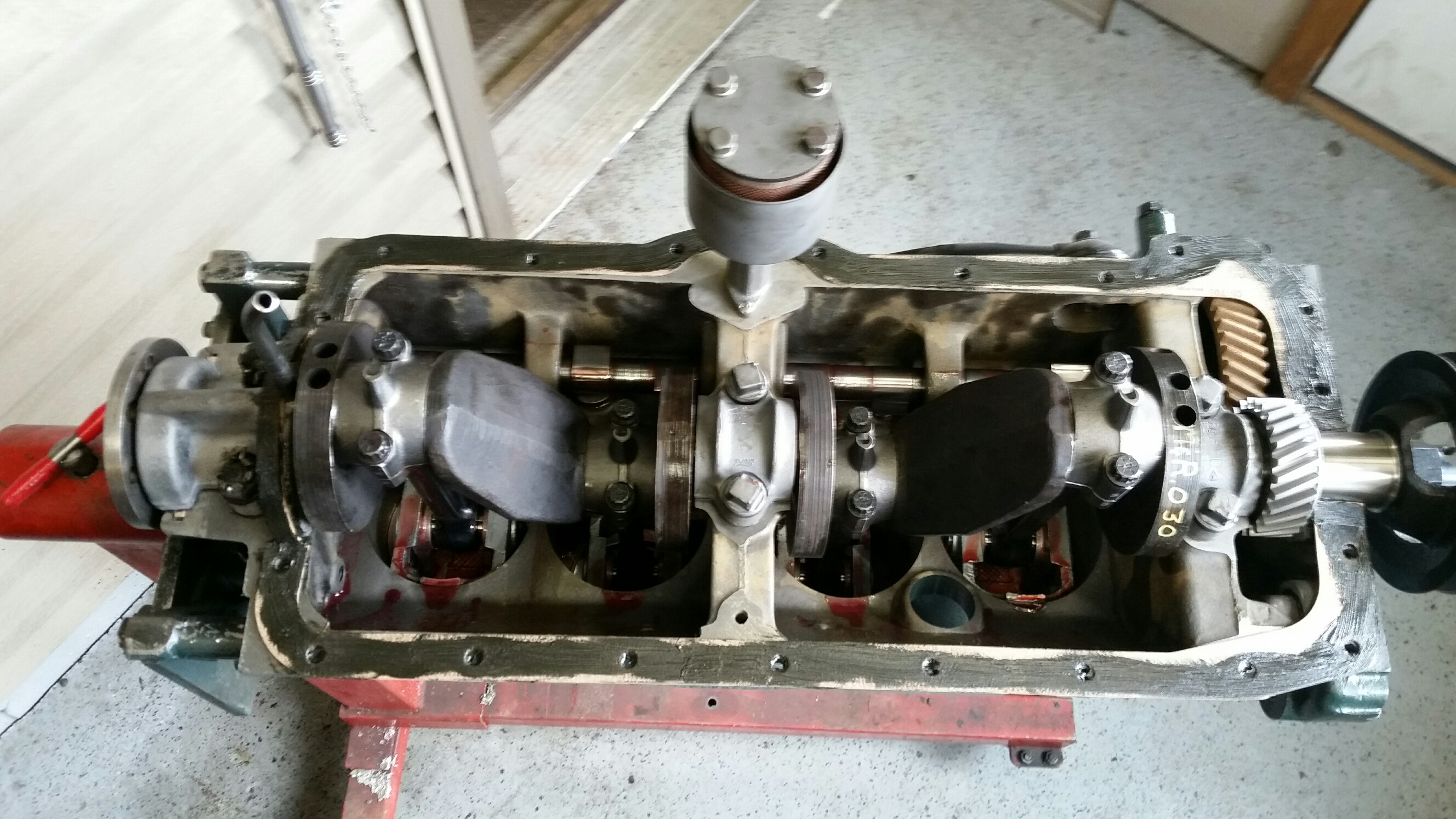

Insert bearing Model A engines I have completed,

Where are they?

Minnesota: 240 Inserted bearing Model A & B engines

North Dakota: 2 Inserted engines

Iowa: 14 Model A & B Engines

Wisconsin: 31

Michigan: 7 Inserted Touring

Colorado: 1 inserted Engine

California: 6 Inserted Engines

Louisiana: 1 inserted Engine

Texas: 1 inserted Engine

Burtz engines: 19

Currently working on: 3 and 1 Burtz engines

The photo to the right is of Mt. Denali in Alaska. I toured Canada, Alaska and northwestern United States this past summer. I was on the road 59 days. During this trip, I logged 11,500 miles. I camped along the way in a clam-shell teardrop. The Miller Hi-Speed Head and Burtz engine worked flawlessly.

Update: 10/7/25

I now have a little over 41,000 miles on my Miller Hi-Speed Head topped Burtz engine. It has been running well and I am very satisfied with both the head and the block.

New projects:

I currently have 6 Burtz engine kits in-stock. One is spoken for. I have three additional customers engines in the shop for partial rebuilding and service work.

I started on a speedster/Ute I have been planning to build. It will have: Standard frame, wheelbase shortened 13.5”, 5-6” lowered front end, synchronized transmission, cowl from a ‘29 Fordor, short box to haul stuff. The intent is to put in a hot “B” engine with a girdle and maybe a Miller 8-Port head. There are a couple photos below….

****I currently am helping family with a building project. Due to this project, I am not taking in or scheduling any new motor work. I will post, on this website, when I am again taking in motors.

Exception: I’ll always make time available to build another Burtz!

Thank you!

After three years of on and off work, the clam shell teardrop and '31 are ready to go. During the summer of 2023, I completed a 11,500 mile round trip to Alaska and areas of Canada from Minnesota. I was one day short of two months on the road. The car and camper held up to the task. I made it to Deadhorse on the north slope as far as you can drive. What a trip!